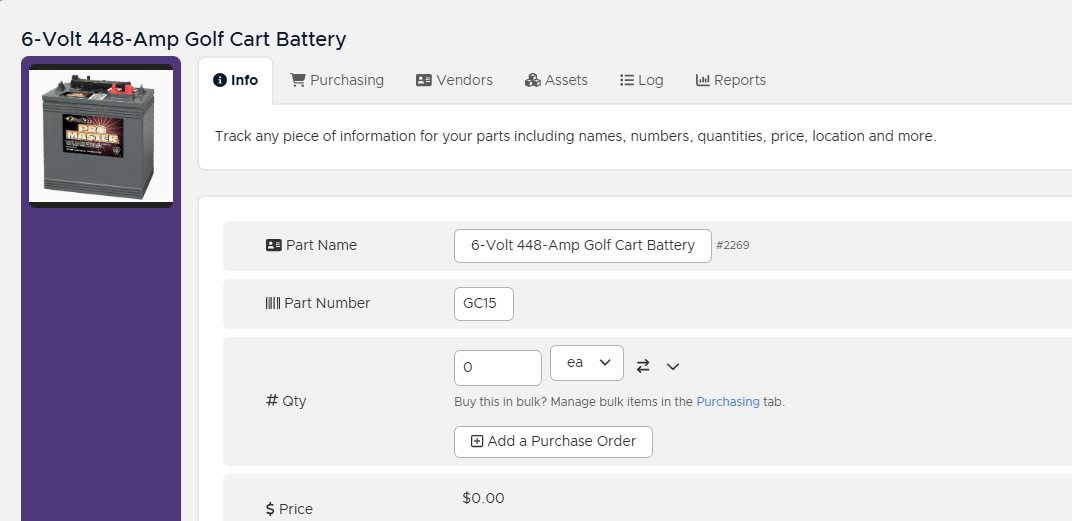

The current system display logic can cause confusion by showing parts as available for a task even when the actual inventory is zero. This happens because the system combines general stock with parts tied to Purchase Orders (POs) when calculating availability. As a result, users may mistakenly believe a part is in stock and usable, when in reality it is not.

Current Limitations

- Misleading Availability: Parts with zero inventory still appear available for use on tasks.

- Combined Stock Display: The system merges general stock and PO stock without distinguishing between them.

- User Confusion: Technicians may assume they can allocate parts immediately when they cannot.

General Example

A technician is assigning parts to a task and sees a part listed as available. When they attempt to use it, they discover the actual inventory is zero, and the “availability” was inflated by... This causes workflow delays and frustration.

Requested Enhancements

- Real-Time Inventory Accuracy

Ensure parts with zero current stock are clearly shown as unavailable for task use. - Separate PO vs. General Stock Display

Visually distinguish between inventory on-hand and inventory tied to pending POs. - Clearer Availability Logic

Update the availability calculation and display so that only usable stock is shown as available.

Business Value

- Accuracy: Prevents false assumptions about stock levels.

- Efficiency: Reduces wasted time caused by assigning parts that are not actually available.

- Clarity: Makes it clear what stock is ready for use versus pending receipt.

- Trust: Builds user confidence in the system’s inventory tracking.