I’ve seen lots of questions about QR codes so I thought I would post a little about how we use them in case it generates any ideas for others.

Student Room WO Requests

To make it easier for students to quickly submit work requests we used Avery labels and printed out a code for every room on campus. This isn’t too bad once you download the needed assets in excel and mail merge them on the Avery website. We put them on the door frames or above the light switch so they are easy to spot. There has been a dramatic increase in student work requests which is helpful for catching issues way sooner than we normally do at the end of the school year.

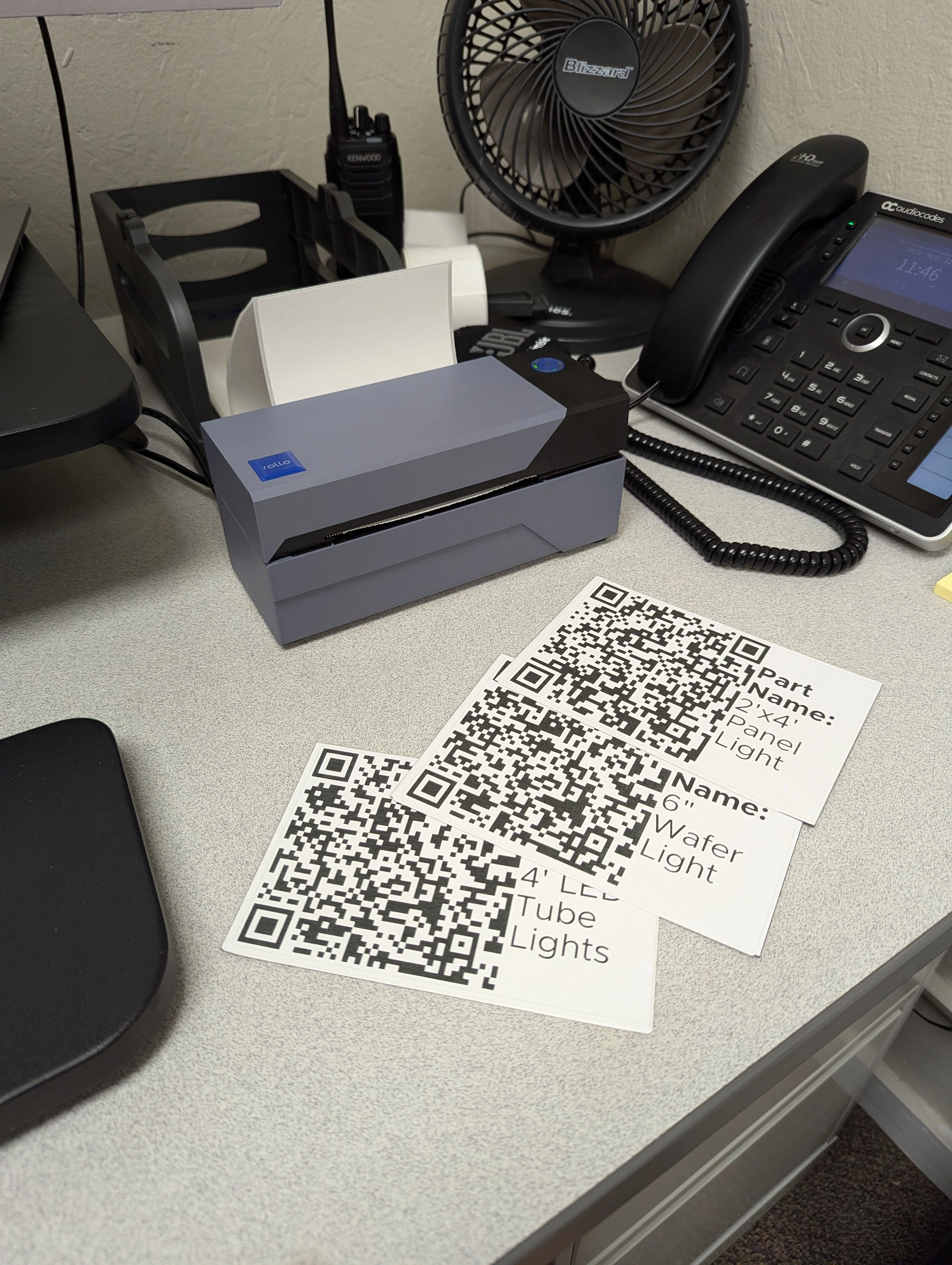

Magnetic Warehouse Tags

We bought a label maker on Amazon so we could create individual labels whenever we need them instead of having to use full label sheets in our regular printer. Another advantage is that we can make 4”x6” labels that are much larger than our standard ones. We stick these labels on magnetic tags so we can move them around the warehouse when parts get relocated.

Metal Weather Resistant Request Codes

A post I saw on the Limble community inspired me to try a new way of making QR codes. We purchased a laser engraver (X Tool S1) to start using metal tags for areas where paper tags get destroyed. Our first project was to identify and tag each lamp post on campus (286 total). I added them into Limble, dropped a pin for their location, and added a location description field as well.

We bought anodized aluminum tags from Amazon and used our laser engraving software to generate a QR code for each one. Then we printed them, sprayed them with four coats of spar varnish and are drilling them into each lamp post. Last thing is to update the picture of each one for Limble.

Previously, Campus Safety would wrap caution tape around a light that was burned out (Not only ugly but often mistaken for trash and removed) but now they can simply scan the QR code to submit. If a work order has already been submitted Limble will point that out to the submitter. The technician then gets the work order with a specific lamp post number, mapped location, and picture so they know what they need for the job. We also plan on adding what type of light bulb goes in each one. We just need a little more time to add all our light bulbs into parts inventory so we can link them together.

I would love to see how others are using QR codes in different ways to inspire us with new ideas!